Sakehitosuji is brewed by polishing rare and valuable Omachi-rice of the Karube district.

Because each and every process has deep impact on the quality of sake,

distinguished taste of Sakehitosuji is made possible. We control the quality of

Sakehitosuji with unceasing care until the very last minute of shipping.

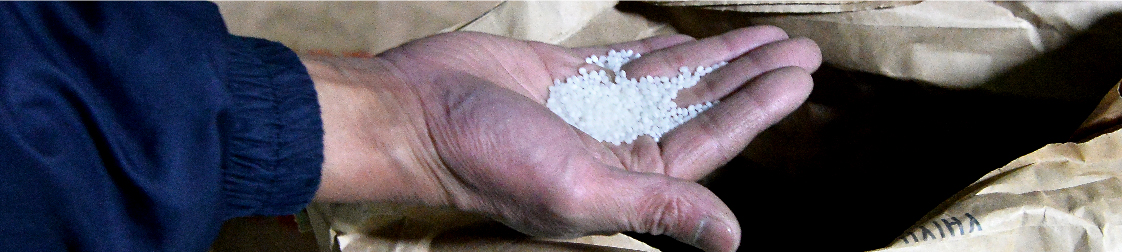

Step 1

Rice Milling

Components on the outer layer of brown rice has great effect on the taste of sake, and too much of it will deteriorate the taste. So the outer layer is removed, leaving only the core of the rice.

This removing or the polishing rate is called seimai-buai , and the ratio is stipulated as follows:

| Requirements such as name | ingredients | seimai-buai | rice malt ratio | flavor etc |

|---|---|---|---|---|

| ginjo-shu | rice, malted rice, brewer's alcohol | less than or equal to 60% | 15% or more ginjo | particular flavor, good color |

| daiginjo-shu | rice, malted rice, brewer's alcohol | less than or equal to 50% | 15% or more ginjo | particular flavor, good color |

| junmai-shu("pure rice sake") | rice, malted rice | - | 15% or more | good flavor, good color |

| junmai-ginjo-shu | rice, malted rice | less than or equal to 60% | 15% or more ginjo | particular flavor, good color |

| junmai-daiginjo-shu | rice, malted rice | less than or equal to 50% | 15% or more ginjo | particular flavor, good color |

| special junmai-shu | rice, malted rice | less than or equal to 60% or special brewing method (information label rquired) | 15% or more | particular flavor, excellent color |

| hon-ginjo-shu | rice, malted rice, brewer's alcohol | less than or equal to 60% | 15% or more | particular flavor, good color |

| special hon-jozo-shu | rice, malted rice, brewer's alcohol | less than or equal to 60% or special brewing method (information label required) | 15% or more | particular flavor, excellent color |

Step 2

1. Rice Washing

In this process, we bag the rice 15 kilograms each, and wash them by hand so as to wash away the bran on the outer layer of the rice grains.

Omachi- rice is soft and may crack at this washing process or the following soaking process, so we wash them with great care.

2. Maceration (Shinseki)

We soak the washed rice to attain water content necessary for the subsequent "Steaming" process. This process is called "Soaking" or shinseki.

This process is controlled on second-time scale, and we pay extra caution for the rice to attain desired moisture content.

3. Steaming

Next step is "Steaming"

Raw starch in rice as itself is hard to be broken down by glucose, so we steam (heat) the rice and alter the raw starch to α starch , which is easily convertible (easily affected by yeast or koji).

We also pasteurize it at the same time.

4. Cooling

The next step is “Cooling”, a process in which we cool the steamed rice to attain optimum temperature for fermentation. This process also has the objective to get rid of moisture on the outer part of rice to acquire ideal state of rice for fermentation- hard outer layer and soft the inner core.

We need to be careful not the let the rice cool too much.

Step 3

1. Rice Washing

The process of converting starch to glucose in sake brewing process is called malt making or seikiku.

It's the most important process in sake brewing, and there is even an old saying about sake brewing which goes “First koji(seikiku), second moto , third tukuri(moromi) ”.

The key to seikiku process is temperature control. It has several steps such as "hikikomi" "yukamomi" "kirikaeshi" "mori" "nakashigoto" "shimaishigoto", and it's essential to keep the appropriate temperature at each step.

2. Starter Mash (Shubo)

Then next comes "Starter Mash" or shubo (also called moto).

Shubo means mother of sake, and for good fermentation, we need to create starter mash prior to fermentation.

The point of mash making is to get rid of contaminating bacteria and to cultivate only the good yeast.

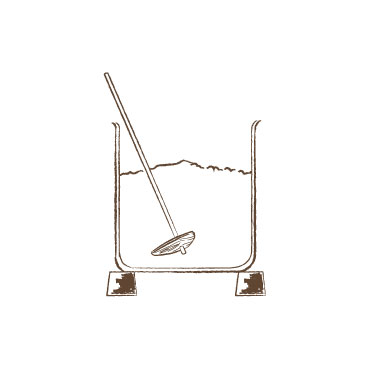

3. Must (moromi)

Then comes or Must ,or moromi (it means "fermentation" or "brewing").

It's the heart of sake brewing process, and the reason we check the quality of koji and shubo is for this process to go as planned, and to obtain the desired quality of sake.

First we put shubo in the jar, then we add water, koji, steamed rice in 3 separate stages (called hatuzoe, nakazoe, and tomezoe) to increase shubo effectively..

The important factor at this stage is again temperature control. By keeping the best temperature, we can obtain the desired quality of sake.

Step 4

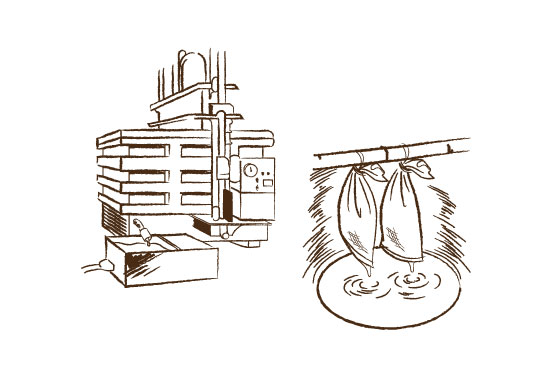

1. Extraction (Joso)

When fermentation level passes its peak, we check the contents for rate of sake, and alcohol concentration, and if the condition is right, we separate the sake from sake lees by pressing them in bags or hanging the bags and letting sake to drip out.

This process is called "Extraction" or joso.

2. Storage

The sake (raw sake) obtained at Extraction stage is stored in a tank until "Bottling".

During Storage, maturation of flavor occurs and the rough taste of sake becomes round and smooth.

But if the sake is matured too much, color, aroma and taste deteriorate, so appropriate temperature control is essential at this stage.

Step 5

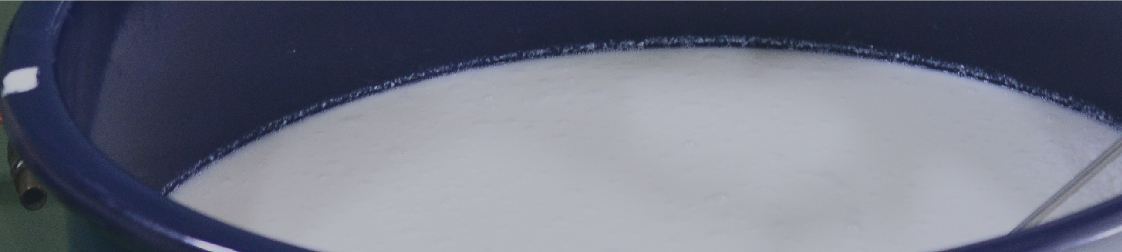

1. Filtration

"Filtering" is the process in which stored raw sake is refined for sales.The objective here is to remove small particles in raw sake.

*There is also a type of sake that skip this process- these are called Unfilitered, or muroka.

2. Bottling

The process of putting filtered sake into bottles and preparing them for sales is called "Bottling". In general, sake is pasteurized at this stage, and at Toshimori SAKE Brewery, we pasteurize the sake and then pass the bottled sake through bottle coolers and cool them down to prevent deterioration of flavor.

Sakehitosuji is made through these processes, and is delivered to you.